Mold Injection

NOVAPAX produces technical plastic parts from thermoplastics mainly for the automotive industry but also for other sectors such as construction, electronics, electrical, medical, sanitary etc Products are of high quality and made with high precision which is achieved by the most advanced machines of mold construction and mold injection.

Our biggest customers are being served worldwide.

For a world-wide leader in supplemental restraint systems and air bags we produce all parts around seat belts such as retractors, tensioners, height adjusters and buckles, as well as the red button. Some of these parts are supplied by more than 20 million pieces per year. We remain competitive by a.o. increasing the number of cavities in the molds, e.g. 16 instead of 8 while fully staying within the required tolerances. We produce parts of airbags that must be 100% functional in case of a car crash.

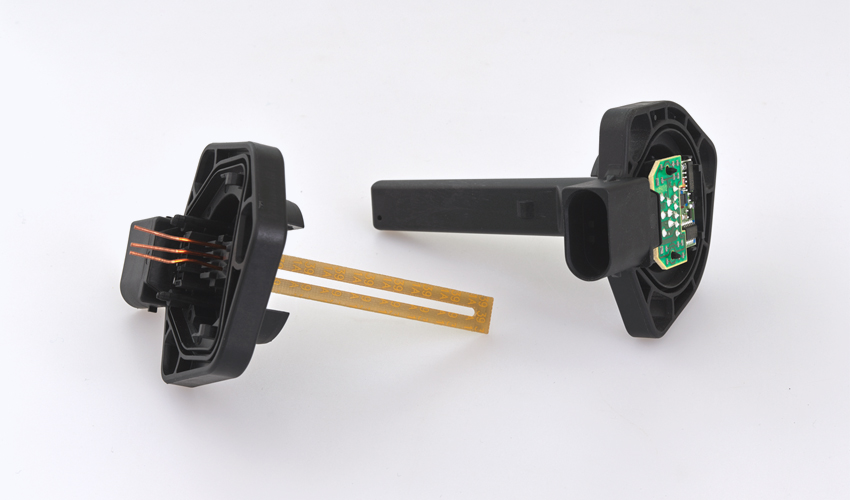

For the market leader in electronics and car lamps Novapax manufactures ca. 100 different articles, including a.o. hybrid parts with overmolded contacts, sockets and magnets. Other parts are laser-labelled or ultrasound-welded. A number of different gas pedals are also part of our portfolio that have to meet strict quality criteria.

In the area of car door lock systems and window opening systems, we supply a.o. gear boxes and cable drums to open car windows, and two-component clips to fasten the interior lining of car doors. These parts are needed by many brands which results in production volumes of up to 20 million per year. Here also quality criteria are very high.

The following customers do not reach the sales numbers of the three previous ones. They are however important as they reduce dependencies and help to diversify products and production technologies.

For the construction industry, we deliver systems of fire prevention and systems to integrate media in buildings. Guaranties must be given for 20 years which is unusual and requires an excellent quality of building elements.

For the medical industry, Novapax develops and delivers lotion dispenser systems.

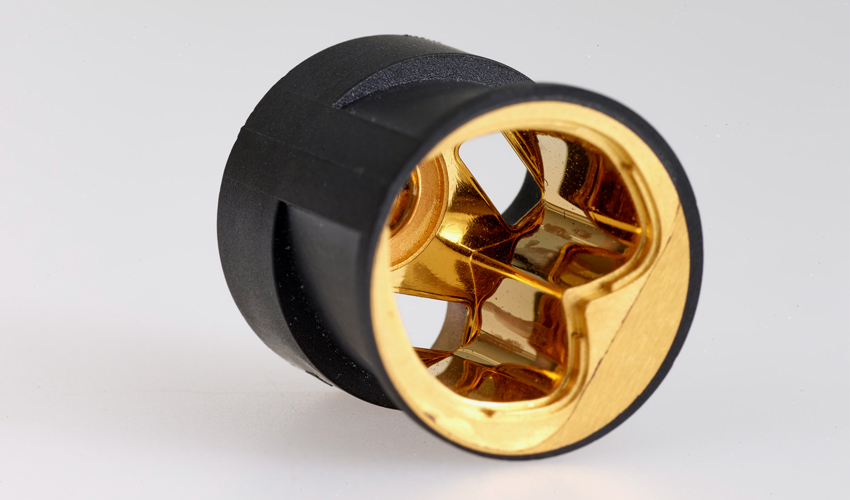

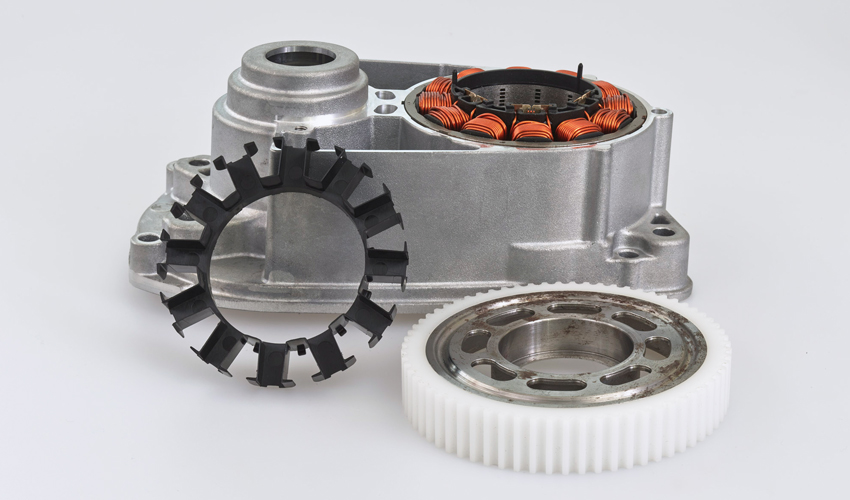

A well-known manufacturer of ventilator motors obtains from Novapax technical plastic parts in various sizes, including end caps for motor housing and hybrid parts in form of rotors.

For household appliances, Novapax produces parts of water fittings using high performance plastics.

It is normal that some customers leave while new customers arrive. The list of customers here is not exhaustive, but it should give an idea about the range of NOVAPAX products.

NOVAPAX offers 75 years of finding plastic solutions and is always open for new ways of production.

Management

Heiko Kurzmann